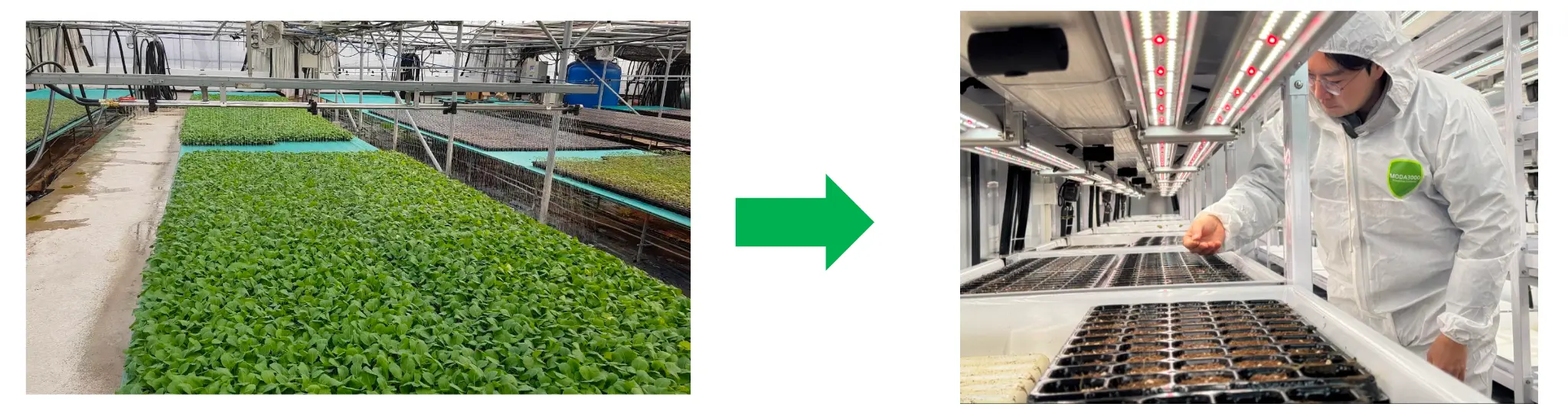

The global challenge of feeding a growing population while grappling with climate change and resource scarcity has pushed agriculture to the brink of a technological revolution. At the forefront of this transformation is Infarmight, a company that has redefined controlled environment agriculture (CEA) not just with innovative hardware, but with a sophisticated, data-driven software ecosystem. The true secret to Infarmight’s consistently perfect crops lies not in the vertical stacks of its farms, but in the invisible, intelligent layer of data analytics and machine learning that governs every single plant’s life cycle. This is an in-depth look at the Infarmight Monitoring System (IMS), the digital brain that powers the farm of the future.

The Invisible Hand: Why Software is the New Soil

Traditional farming relies on intuition, experience, and historical data, often leading to variability and waste. Infarmight’s philosophy is simple: farming is a problem of optimization, and optimization requires data. The IMS is a comprehensive platform designed to eliminate guesswork, replacing it with predictive models and prescriptive actions. It is the central nervous system that connects every sensor, every actuator, and every plant in the network, ensuring that environmental conditions are not just stable, but perfectly tailored to the genetic potential of each crop variety.

The shift from hardware-centric farming to software-centric farming is the core of Infarmight’s innovation. While the physical infrastructure provides the controlled environment, the IMS provides the intelligence to manage it. This intelligence is built on three foundational pillars: massive data ingestion, real-time processing, and advanced algorithmic decision-making.

Section 1: The Sensor Network – Data Ingestion at the Source

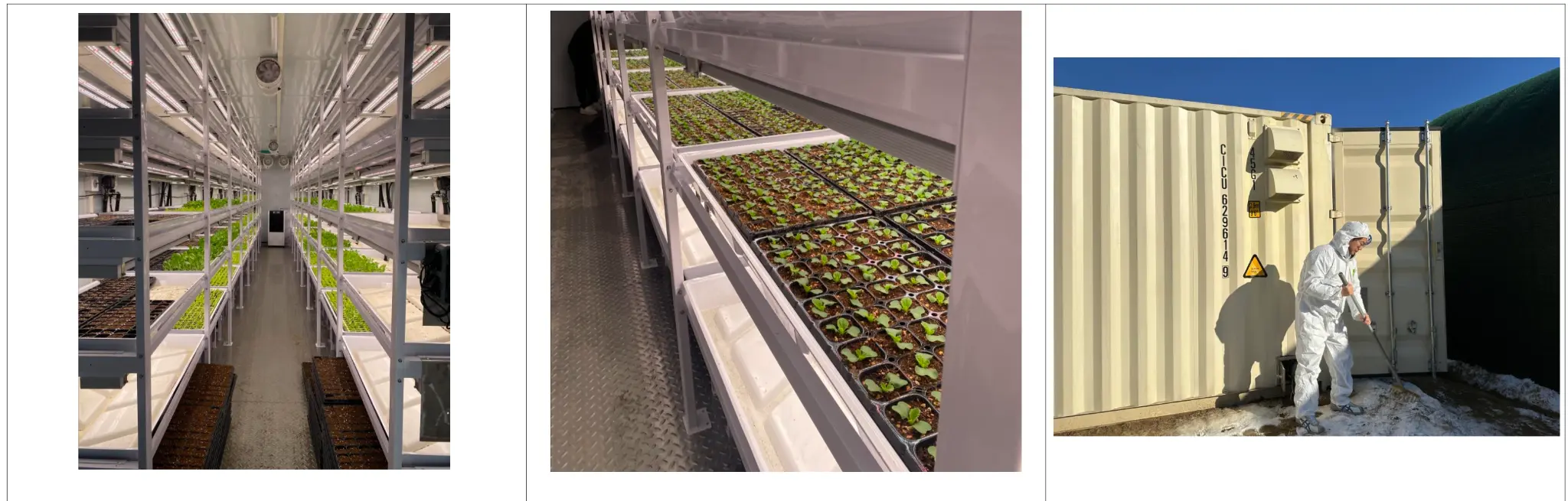

The foundation of the IMS is a dense, hyper-localized network of Internet of Things (IoT) sensors. Unlike traditional greenhouses that might measure temperature and humidity at a few points, Infarmight’s farms are instrumented down to the individual plant level, creating a digital twin of the entire growing environment.

The Data Streams

The IMS ingests hundreds of data points per second from multiple sources:

- Environmental Sensors: Monitoring air temperature, relative humidity, CO2 concentration, and air velocity within the growing chamber.

- Hydroponic/Aeroponic Sensors: Tracking the nutrient solution’s critical parameters: pH, Electrical Conductivity (EC), Dissolved Oxygen (DO), and specific ion concentrations (e.g., Nitrate, Phosphate, Potassium).

- Spectral Light Sensors: Measuring the precise intensity and spectrum of LED lighting, ensuring the Photosynthetically Active Radiation (PAR) is optimal for the current growth stage.

- Computer Vision Systems: High-resolution cameras and 3D scanners continuously monitor plant morphology, leaf area index (LAI), color, and growth rate. This is the primary source for early disease and stress detection.

This massive influx of data is first processed at the edge—using local computing units within the farm—to filter noise, compress the data, and perform initial anomaly checks before transmitting the refined stream to the central cloud platform. This edge-to-cloud architecture ensures low latency for critical, real-time adjustments.

Section 2: The Infarmight Data Platform (IDP): Architecture and Backbone

The sheer volume and velocity of the data generated by a global network of Infarmight farms require a robust and scalable data platform. The Infarmight Data Platform (IDP) is built on a modern, cloud-native architecture designed for high-throughput stream processing.

Real-Time Data Pipelines

The IDP utilizes a combination of technologies to handle the data:

- Data Lakehouse: A hybrid architecture combining the flexibility of a data lake (for raw, unstructured sensor data and images) with the structure and performance of a data warehouse (for processed, time-series data).

- Stream Processing Engines: Tools like Apache Kafka and Flink are used to process data streams in real-time, enabling immediate feedback loops. For example, if a sensor detects a sudden drop in pH, the system can trigger a corrective action within milliseconds, long before a human operator would even notice the deviation.

- Digital Crop Recipes: At the heart of the IDP are the “Digital Crop Recipes”—detailed, parameterized growth protocols for every crop. These recipes are not static; they are dynamic models that serve as the target state for the entire system. The IMS constantly compares real-time sensor data against the current recipe stage and calculates the necessary adjustments.

This architecture allows Infarmight to maintain a single, unified view of every plant across its entire global network, enabling cross-farm performance benchmarking and rapid deployment of optimized recipes.

Section 3: AI and Machine Learning – The Brain of the Farm

The true value of the IMS is unlocked by its suite of Artificial Intelligence and Machine Learning (AI/ML) models. These models transform raw data into actionable insights and, crucially, into autonomous control commands.

Predictive and Prescriptive Analytics

The AI models fall into three main categories:

- Predictive Yield Modeling: Using historical growth data, environmental inputs, and genetic information, the IMS can predict the final yield and harvest date with high accuracy. This is vital for supply chain management and ensuring fresh produce reaches customers at peak quality.

- Anomaly Detection and Health Monitoring: Computer vision models, trained on millions of images of healthy and stressed plants, can detect the earliest signs of nutrient deficiency, pest infestation, or disease. These models often spot issues days before they become visible to the human eye, allowing for hyper-localized, non-chemical interventions.

- Prescriptive Environmental Control: These are the most complex models. They don’t just predict what will happen; they prescribe what should be done. For a specific crop at a specific growth stage, the model might determine that a 5% increase in blue light spectrum, a 2°C drop in root zone temperature, and a 0.1 EC adjustment will maximize biomass accumulation over the next 48 hours. The system then autonomously executes these changes.

The continuous feedback loop is what makes the IMS so powerful. Every harvest, every successful intervention, and every failed experiment feeds back into the ML models, refining the Digital Crop Recipes and making the entire system smarter over time. This is a self-optimizing farm.

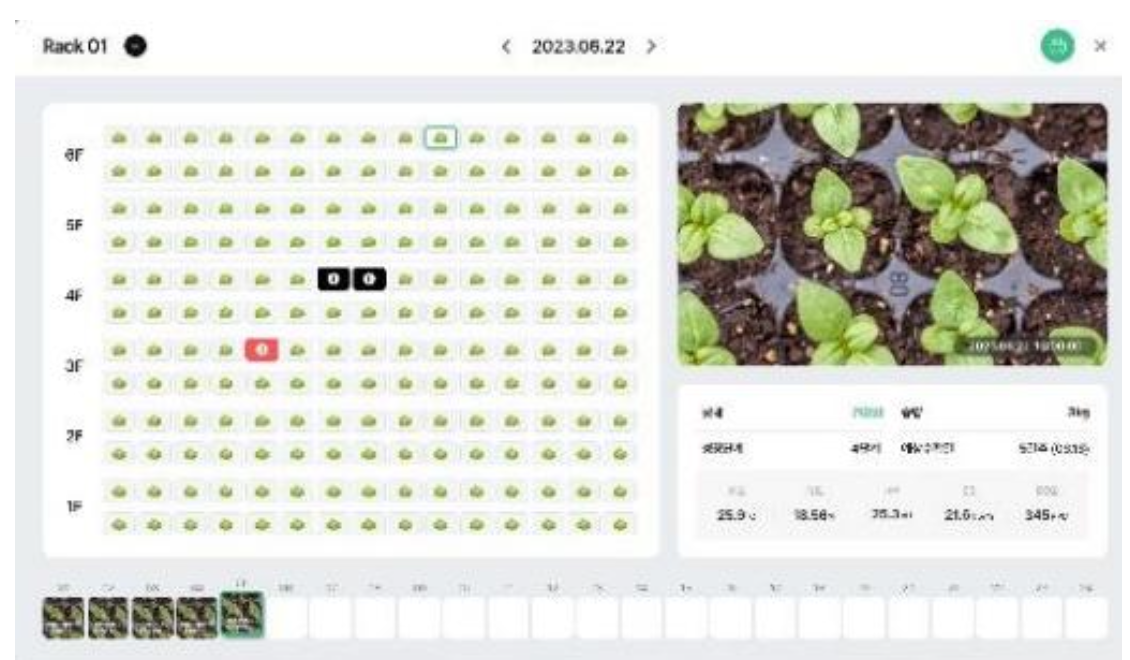

Section 4: The Human-Machine Interface – The IMS Dashboard

While the IMS is largely autonomous, human oversight and strategic decision-making remain essential. The IMS Dashboard is the window into the farm’s operations, designed for clarity, efficiency, and deep data exploration.

Data Visualization and Interaction

The dashboard provides farm managers with a tiered view of operations:

- Global Overview: A high-level status of all farms, highlighting key performance indicators (KPIs) like overall yield forecast, resource consumption efficiency (Water Use Efficiency – WUE, Energy Use Efficiency – EUE), and any critical alerts.

- Farm-Level View: Detailed schematics of a single farm, showing the status of each growing rack, current environmental parameters, and a summary of active recipes.

- Plant-Level Drilldown: The ability to select a specific batch or even a single plant and view its entire historical data profile, including growth curve, light exposure, and nutrient history.

The interface is not just for viewing; it’s for interaction. Farm managers can use the dashboard to A/B test new recipes, deploy software updates, and override autonomous controls when necessary.

Key Metrics and Decision Support

To illustrate the depth of data available, here is a simplified view of the key metrics the IMS tracks and optimizes:

| Metric | Description | Optimization Goal | IMS Tool/Model |

|---|---|---|---|

| Water Use Efficiency (WUE) | Grams of dry biomass produced per liter of water consumed. | Maximize WUE to reduce operational costs and environmental impact. | Prescriptive Irrigation Model |

| Light Use Efficiency (LUE) | Grams of dry biomass produced per mole of light (PAR) received. | Optimize light spectrum and intensity to maximize photosynthesis while minimizing energy use. | Spectral Optimization Algorithm |

| Harvest Uniformity Index (HUI) | Statistical measure of the variance in size and weight across a harvested batch. | Achieve near-perfect uniformity for predictable packaging and quality control. | Growth Rate Synchronization Model |

| Nutrient Uptake Rate (NUR) | Real-time rate at which specific ions are absorbed by the plants. | Fine-tune nutrient delivery to match the plant’s exact metabolic needs at any given moment. | Dynamic EC/pH Adjustment |

This table represents just a fraction of the data points, but it highlights the system’s focus on measurable, actionable optimization.

Section 5: Precision Agriculture in Action – Case Studies

The power of the IMS is best demonstrated through its application in specific crop cycles.

Case Study 1: Basil’s Perfect Aroma

Basil is highly sensitive to environmental stress, which can quickly lead to bolting (flowering) and a loss of its characteristic aroma.

- The Challenge: Maximizing leaf size and oil content while preventing premature bolting.

- IMS Solution: The system uses its Growth Rate Synchronization Model to maintain a tight control over the temperature differential between day and night (DIF). By slightly lowering the night temperature and precisely controlling the red-to-far-red light ratio, the IMS suppresses the flowering hormone. Simultaneously, the Dynamic EC/pH Adjustment model ensures a slightly elevated potassium level in the final week of growth, which is correlated with higher essential oil production. The result is a basil crop with a consistently intense flavor profile, harvested at the exact moment of peak quality.

Case Study 2: Lettuce and the Anomaly Detector

In a large-scale lettuce operation, a single farm was experiencing a subtle, localized slowdown in growth that was invisible to the naked eye.

- The Challenge: Identifying the root cause of a 3% growth lag in a specific rack.

- IMS Solution: The Anomaly Detection Model, analyzing data from the computer vision system, flagged a minor, non-critical deviation in leaf color saturation and turgidity in one corner of the rack. The system cross-referenced this with the environmental data and found that a single air circulation fan was operating at 98% efficiency instead of 100%, creating a micro-climate with slightly higher humidity and lower CO2 exchange. The IMS automatically adjusted the fan speed and the CO2 injection rate for that specific zone, correcting the issue before the 3% lag could turn into a full-blown crop loss. This level of granular, autonomous correction is impossible without a data-driven platform.

Section 6: Scalability and Sustainability – The Future of Farming

The IMS is not just a tool for optimizing a single farm; it is the engine for scaling Infarmight’s operations globally and ensuring unparalleled sustainability.

Global Recipe Deployment

Because the entire system is software-defined, Infarmight can instantly deploy a new, optimized crop recipe to all its farms worldwide. If the AI models discover a 1% improvement in yield for a specific tomato variety in a farm in Europe, that improvement can be pushed to farms in Asia and North America within minutes. This rapid iteration and global knowledge sharing accelerate agricultural innovation at a pace never before seen.

Resource Efficiency Driven by Data

The data-driven approach directly translates into sustainability gains:

- Water: The Prescriptive Irrigation Model ensures that water is delivered only when and where it is needed, minimizing runoff and evaporation. Infarmight’s farms achieve up to 95% less water usage compared to field farming, a metric constantly monitored and optimized by the IMS.

- Energy: The Spectral Optimization Algorithm and the environmental control models work in tandem to minimize energy consumption. By predicting the exact light and temperature needs, the system avoids over-lighting or over-cooling, which are major energy drains in CEA. The IMS can even integrate with local energy markets, slightly adjusting non-critical parameters during peak pricing hours to reduce costs without impacting crop health.

- Nutrients: The Dynamic EC/pH Adjustment model minimizes nutrient waste by maintaining a perfectly balanced solution, reducing the need for large-scale solution dumps.

Conclusion: The Harvest of Intelligence

Infarmight’s success is a testament to the power of integrating cutting-edge software and data science into the most ancient of human endeavors: farming. The Infarmight Monitoring System (IMS) is more than just a collection of sensors and algorithms; it is a continuously learning, self-optimizing platform that guarantees quality, maximizes yield, and drives sustainability. By treating the farm as a complex, dynamic data problem, Infarmight is not just growing food; it is cultivating intelligence, ensuring that the future of agriculture is not only abundant but also perfectly precise. The era of the digital farmer has arrived, and the harvest is looking smarter than ever.